Price includes both left and right discs (1 pair)

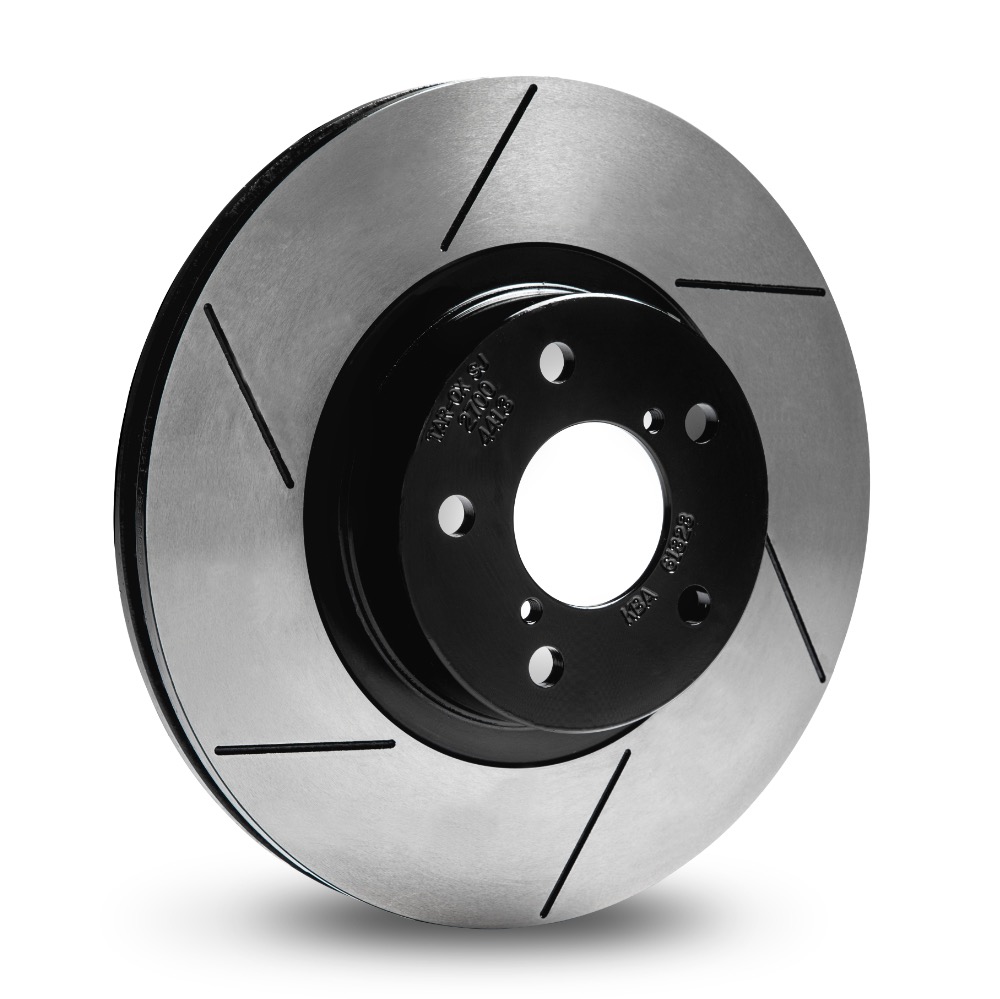

- F2000 - long curved grooves

- G88 - 40 straight grooves

- Sport Japan - drilled and grooved

- C83 - short straight grooves

- D95 - drilled only

- ZERO - plain braking surface

Some options may not be available

€357.60 – €405.60Price range: €357.60 through €405.60

Price includes both left and right discs (1 pair)

Some options may not be available

They're expensive, right? Reassuringly so, yeah. Here's why...

All TAROX performance brake discs are based on original equipment specification, TUV approved castings, heat treated for strength and hand finished to ensure the flattest possible braking surface. We take a high quality product that is already complete and certified as fit for use, and we make it better.

First up is our heat treatment. Precision heat treatment of metals is a method of unifying the microstructure of the alloy to improve strength and hardness resulting in a better brake disc. It's just science, Google it. We have perfected our heat treatment technique specific to brake discs through decades of experience.

The heat treated disc then receives one of our performance disc facings. They're all functional, nothing just for show. You won't find any dimples on a TAROX disc. Each style that we offer is purposeful in its own unique way and all of them offer increased performance over a standard disc. Whether you're looking for improved pedal feel, cooler operating temperatures, or a bit of both, you'll get a disc that performs as good as it looks.

After machining, the discs are treated to a special anti rust coating. We want our discs to continue to look amazing on your car for their entire lifespan, not just when you unbox them. Using Cataphoresis (more science), a special electronically controlled coating is applied which is super durable and will not burn off. It protects the unswept parts of the disc from the elements, even the internal cooling ventilation of the disc is protected.

Finally, both disc surfaces are simultaneously polished on bespoke hand operated machinery. This crucial process ensures that the surfaces are both perfectly parallel and perfectly flat. The surface of a TAROX disc is machined to a tolerance approaching 0.05mm. The process of achieving a perfectly flat surface not only enables the brake pad to bed in quickly and more effectively, but it reduces the chances of the disc developing lateral oscillation (run out). A perfectly machined part with a high shine and oozing quality is just the icing on the cake. Fun Fact: the machines used for this process are recalibrated every three runs.

First developed for use in touring cars over 20 years ago and often found in the TAROX range of big brake kits, the F2000 has forged a reputation as the toughest performance aftermarket brake disc available. We have even observed a number of high end vehicle manufacturers using F2000 ‘style’ discs on their range topping models.

The G88’s grooves feature an edge to edge design, ensuring absolute maximum dissipation of heat, while incorporating a chamfered leading edge, which ensures that the life of the brake pad is not decreased. The unique grooves allow the G88 to run cooler than any other performance brake disc tested against it. Available for discs up to 330mm.

Sport Japan discs are one of the only aftermarket performance discs to still feature fully drilled holes. To ensure ultimate performance and durability all Sport Japan discs feature countersunk holes strategically placed so as not to affect the discs structural integrity. An additional 6 grooves on the braking surface act like a wiper, keeping the brake pad from glazing and removing excess dust while providing additional cooling.

The original groover. Created in March 1983 the C83 was the first grooved disc ever offered for road going applications. Simple and still effective, the straight grooves sweep the pad keeping the surface optimised for every application of the pedal. Ideal for applications where strength takes precedence over cooling and noise output is minimum. Excellent choice for road cars.

Unlike many competitor discs, our D95 pattern features fully drilled holes which are countersunk to help prevent surface fracturing. Providing a path for hot gases and water to escape, the holes in the D95 pattern create a disc ideal for those needing a solution where ultimate cooling takes precedence over longevity and noise.

Although plain in appearance, the ZERO discs are far from an original disc. TAROX ZERO discs are made from special high grade casts submitted to several levels of heat treatment. An outstanding resistance to high temperatures prevents warping and cracks. The final hand finishing leaves them incredibly smooth allowing them to mate to pads efficiently, increasing life of the disc and pad.

For the full specification of this particular disc, please see the 'ADDITIONAL INFORMATION' tab above.

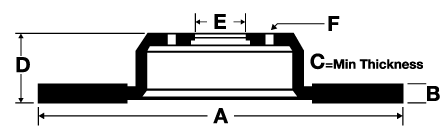

| TAROX Code | |

|---|---|

| Quantity | 2 Discs |

| Axle | Front |

| Disc Type | Vented |

| Vehicle Year | 2004 > |

| Vehicle Engine Size | 1.9 |

| Disc Diameter | 288 |

| Disc Thickness | 25.0 |

| Minimum Disc Thickness | 22.0 |

| Offset (Disc Height) | 50.0 |

| Centre Bore Diameter | 65.0 |

| Stud Hole Arrangement | 5 |

| Make | Model | Year |

|---|---|---|

| Volkswagen | Caddy (04-) |

This website lists our entire range - it is not linked to our stock system. If you would like to check the availability of any items before ordering please call the office or get in touch via the Contact Us page.

Brake kits, Bespoke discs, and Racing Rotors

All brake kits, Bespoke discs, and racing rotors are manufactured to order at our facility in Northern Italy. Typically, we require 5-7 days to do this. Certain options, such as colour anodising or anti-rust treatment, may extend the assembly time in some cases. On completion of your build, the parts will be shipped to our UK office on the next available weekly consignment. Transit times from Italy to the UK are typically around 7 days. On arrival, your kit will be despatched to your chosen delivery address within 1-2 days.

Brake discs, pads, hoses and fluid

Popular fast moving items are kept in stock and are despatched from our UK office. Orders received before 12pm will be shipped the same day. Items that are not in stock at our UK office will be shipped to the UK from our Italian facility on the next available weekly consignment. On arrival, your order will be despatched to your chosen delivery address within 1-2 days.

Once your order is ready to be despatched from the UK...

Shipping within the UK

Orders being delivered within the UK will be despatched with Parcelforce using their next day service. Text message updates are provided by Parcelforce to those customers who provide mobile phone numbers during checkout.

International Orders

International orders will be despatched using a tracked service once all applicable export paperwork has been completed. We use various couriers for worldwide shipping including TNT, FedEx, and UPS. Customers are responsible for all applicable duties and taxes. Customs import duties (if any) and local taxes are assessed when the package arrives in your country and we are unable to advise on such matters. Please check with your local customs office for detailed information.